In this article

Meeting Food Hygiene Regulation for Manufacturers

Food and drink manufacturing covers the processing and manufacture of many different types of food and drink, e.g. meat, fish, poultry, dairy, grain-mill, bakery, fruit, vegetables, confectionery, sugar, oils, and alcoholic and non-alcoholic beverages. According to the Food & Drink Federation (FDF), there are 10,990 food and drink manufacturing businesses in the UK. Every single one of these businesses, whether small or large, must comply with the law and adopt good food hygiene and safety practices. If they do not, it increases the risk of contamination and can make food unsafe. Contaminated food can make consumers ill, cause injuries and may even be life-threatening in some cases.

Poor hygiene and unsafe practices, such as not cooking or chilling high-risk food sufficiently, and cross-contamination, can cause food poisoning. Allergen products coming into contact with allergen-free ones can result in severe allergic reactions in some people. Physical contaminants can injure the mouth and may even result in choking. These hazards present an even greater risk for those who are vulnerable, such as young children, the elderly, pregnant women, allergy sufferers and people with weakened immune systems.

The overall aim of any business is to be profitable. All food and drink manufacturers will be inspected by Local Authority Environmental Health Officers. They may also be audited if their food safety management systems are certified to specific standards, such as BRCGS Standard for Food Safety, SALSA or ISO 22000. If food hygiene and safety standards are poor during inspections and audits, it can result in enforcement action and a loss of certification. Poor standards may also mean a loss of reputation, costly recalls, stock disposal, a loss of customers and, overall, a decrease in turnover.

This guide will provide manufacturers with general advice on achieving good food safety and hygiene standards. It will also highlight why food safety and hygiene is essential in manufacturing.

Food hygiene legislation for manufacturers

As food operators, all food manufacturers will need to comply with food safety and hygiene legislation.

The main laws are:

- The Food Safety Act (FSA) 1990– Provides a framework for food safety legislation in Great Britain (England, Wales and Scotland). Northern Ireland has different legislation; the Food Safety (Northern Ireland) Order 1991. The FSA 1990 covers food safety, consumer protection, food information etc.

- The Food Safety and Hygiene (England) Regulations 2013 – Created under the FSA 1990. The regulations cover the enforcement of food hygiene and the HACCP principles from Regulation (EC) 852/2004 (retained EU law). There are different regulations for each UK country, e.g.:

– The Food Hygiene (Scotland) Regulations 2006.

– The Food Hygiene (Wales) Regulations 2006.

– The Food Hygiene Regulations (Northern Ireland) 2006. - The Food Information Regulations 2014 – Places duties on food businesses to provide information to consumers on allergens. These regulations were amended by the Food Information (Amendment) (England) Regulations 2019 to include Natasha’s Law, which came into force on 1st October 2021.

Further information on the key regulations is on the Food Standards Agency webpage.

Manufacturers will need to register with their local authority, and some may require additional approval, depending on the type of food or drink manufactured. They will also need relevant insurances, e.g. public liability and employer’s liability.

There will be other applicable laws, depending on the type of manufacturing business. It is the manufacturer’s responsibility to ensure they know and comply with all relevant food safety laws relating to their business. Ignorance of legislation is not a defence.

Environmental Health Officers (EHOs) are responsible for enforcing food safety and hygiene. They have certain powers under the FSA 1990 and various food hygiene regulations. If manufacturers do not comply with legislation, EHOs can issue enforcement notices. For more serious offences and non-compliance of notices, officers may decide to prosecute, which may mean fines, imprisonment and even closure of the business. If consumers are made ill by unsafe food, they may also claim compensation, which can be very costly.

Manufacturer prosecution cases

- A woman had a severe allergic reaction (anaphylaxis) after a food company mistakenly put egg in a pot of tzatziki. Tests found levels of egg protein in the product, but there was no mention of egg on the label. The tzatziki became contaminated, as a dip (containing egg) had been produced on the line before. The company was prosecuted and fined £93,000 (BBC News).

- A food manufacturer was prosecuted and fined £112,500 after giving chicken a longer shelf-life than recommended. They had also ignored a previously issued enforcement notice (BBC News).

- A manufacturing bakery was prosecuted and fined £6,400 after inspectors found mouldy food during a routine inspection (Stroud District Council).

Staff training on food hygiene for manufacturers

Legally, all food operators must ensure that any staff who prepare, handle or sell food are supervised, instructed and trained in food hygiene matters. It does not mean that staff have to have a food hygiene certificate. However, having evidence of this type of training is the best way to demonstrate to EHOs and customers that the business is committed to food safety. It also provides evidence for due diligence purposes in the event of an investigation or legal action.

Staff should receive training in line with their responsibilities, the area where they work and their tasks.

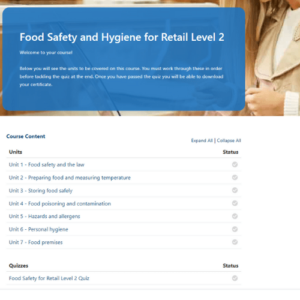

There are different levels of food hygiene training, e.g.:

- Level 1 – Introduction to food hygiene, typically for those handling low-risk food, e.g. wrapped foods. This course may be useful for staff with limited food contact, such as transport and office staff.

- Level 2 – Basic food hygiene certificate for staff preparing, cooking and handling food. Most manufacturing workers will require at least a level 2 course.

- Level 3 – Intermediate food hygiene certificate for those with more responsibilities, e.g. business owners, supervisors, managers and those involved in food safety management systems and HACCP.

Refresher training is also a requirement. The frequency will depend on the nature of the business, its risks, the food manufactured, and the competence of workers.

Food hazards in manufacturing

Food hazards are contaminants that can enter food and potentially cause harm to consumers. The Food Standards Agency (FSA) defines a food hazard as “something that could make food unsafe or unfit to eat”.

There are four different types of food hazards: biological, chemical, physical and allergenic.

Biological

Biological hazards happen when microorganisms contaminate food, and poor practices provide optimal conditions for harmful pathogens to grow. In food manufacturing, contamination may occur due to inadequate and improper storage, preparation, processing (cooking/cooling), packing and distribution of food. It can also result from cross-contamination (e.g. raw foods coming into contact with ready-to-eat foods), poor personal hygiene and using ingredients past their use-by date.

The risk will depend on the type of food/drink manufactured. One that only packs dry foods will be a lower risk than another processing and preserving food (especially high-risk foods, such as dairy, eggs, meat, fish, shellfish and poultry).

Examples of biological hazards include:

- Bacteria, e.g. salmonella, E. coli, listeria, clostridium and campylobacter.

- Fungi, e.g. yeasts and moulds.

- Viruses, e.g. norovirus.

- Parasites, e.g. worms and protozoa.

These microorganisms can cause foodborne illnesses, including food poisoning and intoxication.

It is unlikely consumers will catch the COVID-19 virus from food (Food Standards Agency). However, manufacturers must follow current Government Guidance to reduce the risk to staff and consumers. There is also further guidance – adapting food manufacturing operations during COVID-19.

Chemical

Chemical hazards occur when naturally occurring or human-made substances contaminate food. In food manufacturing, chemical hazards may occur due to cross-contamination, i.e. storing chemicals in food storage areas and using non-food grade chemicals on and around food surfaces/equipment. Chemical contamination can also occur during processing, e.g. acrylamide produced by cooking certain foods at high temperatures may cause cancer.

Examples of chemical hazards include:

- Toxins produced by animals, plants and microorganisms, e.g. by bacteria and moulds.

- Unintentionally added chemicals, e.g. cleaning and maintenance chemicals, pesticides, veterinary drugs and processing-induced chemicals.

- Intentionally added chemicals to food but could be hazardous if used in excess quantities, e.g. flavourings, preservatives, vitamins and colourings. Chemicals can also be added intentionally as a result of a food crime.

Eating food contaminated with chemicals can result in immediate harm to the consumer. It can also cause long-term health effects if exposed to the hazard over time.

Physical

Physical hazards are foreign materials, objects and extraneous matter that can enter food during manufacturing processes but may also be in raw ingredients. In food manufacturing, these may occur due to poor personal hygiene. However, they can also come from packaging, poorly maintained premises and equipment, and pests.

Examples of physical hazards include:

- Natural hazards – Occur naturally in food, e.g. dirt on potatoes, fruit pips and stones, bones in meat and fish and shells from nuts.

- Unnatural hazards – Should not be present in food, e.g. stones, human hair, fingernails (including false fingernails), jewellery, plastic, glass, animal droppings, metal and wood.

These types of hazards can cause injuries to the mouth, teeth and gums. In some cases, physical contaminants can even result in choking, especially in the very young and the elderly. Some can be generally unpleasant to find in food, i.e. a hair or plaster.

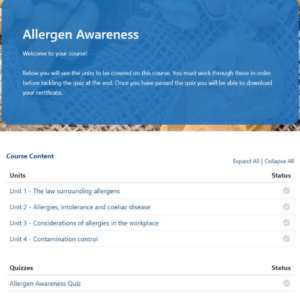

Allergenic

Allergens are proteins that occur naturally in some foods but can contaminate other foods by cross-contact. These types of hazards can cause allergic reactions in food allergy sufferers. In some cases, there is a risk of anaphylaxis in those with severe allergies.

There are 14 recognised allergens, which include:

- Eggs.

- Fish.

- Milk.

- Peanuts (groundnuts).

- Celery (all of the plant, including the root celeriac).

- Mustard (liquid, powder and seeds).

- Tree nuts (almonds, hazelnuts, walnuts etc.).

- Sesame (seeds).

- Lupin (flower and seeds).

- Soybeans.

- Cereals (gluten) (oats, rye and barley).

- Molluscs (oysters, snails and mussels).

- Sulphur dioxide and sulphites.

- Crustaceans (crab, prawns and lobster).

In manufacturing, allergenic hazards are likely to result from storing and processing allergen products where non-allergen products are. As the prosecution case highlighted, allergens can easily contaminate other products if production lines are not separated or cleaned thoroughly. Staff can also inadvertently contaminate products with allergens through poor personal hygiene.

There is potential for all types of food hazards in food manufacturing. The risk will depend on the type of manufacturing business and the food/drink produced. To prevent and control food safety risks, manufacturers must have suitable food safety management systems (based on the principles of HACCP).

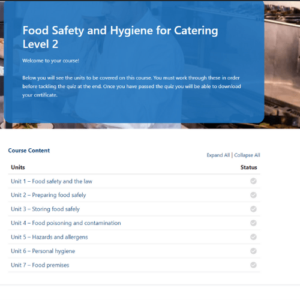

The 4Cs

Manufacturers should have food safety management systems in place to prevent food hazards. They can also use the 4Cs of food hygiene. These are four simple rules to remember for good food hygiene and safety practices.

Cleaning

According to the Food Standards Agency (FSA), a lack of thorough cleaning is one of the most common reasons for prosecution. Cleaning is essential as it stops harmful pathogens and allergens from spreading, discourages pests, and is a legal requirement.

Food manufacturers should have effective cleaning procedures and schedules to ensure that all areas (where food is stored, prepared, processed and transported) are kept clean and safe. Adopting a ‘clean as you go’ approach will help keep areas constantly clean and tidy. It is also important to keep machinery and equipment clean, especially where processing different products on the same line.

Cooking

Some food manufacturers may cook food and then chill it down and pack it ready for sale. They may also have canteens and provide hot food for staff. Food must be cooked thoroughly. If it is undercooked, it can cause food poisoning, particularly with high-risk foods such as meat, poultry, fish and rice. Cooking at the correct temperature for the appropriate time will help kill any harmful bacteria.

If manufacturers do cook as part of their process, it is likely to be in bulk. They may have specialised equipment used for cooking, which often monitors temperatures. It is essential all cooking equipment is in good repair, calibrated and maintained. When cooking food, manufacturers should monitor it closely, as it will be a critical control point (CCP).

The cooking method, time and temperature will depend on the type of food and process. When cooking, food should reach at least 70°C and stay at that temperature for 2 minutes (or at an equivalent temperature and time, i.e. 80°C for 6 seconds). If cooking equipment does not automatically monitor food temperatures, a clean, calibrated probe should be used to ensure food is properly cooked.

If manufacturers reheat any food, e.g. in staff canteens, it should be at least 75°C for 30 seconds. In Scotland, the regulations require reheated food to be at least 82°C. Only reheat food once.

Cross-contamination

Foodborne illnesses usually occur due to the transferring of harmful bacteria between people, food, surfaces and equipment. This is known as cross-contamination, and it is one of the most common causes of food poisoning (FSA). It can also occur with chemicals, e.g. using chemicals on food contact surfaces and equipment. Where allergens are concerned, it is known as cross-contact. This is where products containing allergens are often unintentionally transferred to allergen-free ones.

Manufacturers must ensure they prevent cross-contamination and cross-contact as much as possible in their facilities, which can be achieved by:

- Good personal hygiene, e.g. washing and sanitising hands thoroughly.

- Thoroughly washing salad, fruits and vegetables before processing.

- Having separate areas, production lines, equipment, utensils, clothing and staff for different types of foods, e.g. raw and cooked, and allergen and allergen-free.

- Cleaning and disinfecting production lines, equipment, cleaning materials and utensils before use, between uses and after.

- Storing food correctly, e.g. keeping raw foods away from cooked and ready-to-eat foods and keeping away from chemicals.

- Storing allergenic foods and non-allergenic foods separately, including ingredients and processed food.

- Adopting a high standard of cleanliness at all times.

- Preventing and controlling pests.

- Training staff on avoiding cross-contamination.

Chilling

Certain foods, e.g. those with use-by dates, cooked and ready-to-eat foods, must be stored chilled to be safe. Chilling does not kill harmful bacteria, but it does help to stop them from growing. If food is improperly chilled, it can enter the danger zone and encourage pathogens to grow, increasing the risk of food poisoning.

Manufacturers must ensure that food is properly chilled and stored correctly, for example:

- Ensuring chilled and frozen food is stored at the correct temperature on receipt/delivery and put into storage as soon as possible.

- Ensuring chilled food is kept out of the refrigerator/chiller for the shortest time possible during preparation.

- Ensuring refrigerator/chiller temperatures are at 5°C or below, and freezer temperatures are at least -18°C or below. Vehicles used for transporting food should also be at the correct temperature.

- Ensuring food is stored correctly within refrigerators/chillers, e.g. raw food at the bottom or in separate fridges to ready-to-eat and cooked foods.

- Defrosting frozen foods in accordance with suppliers’ instructions (where applicable).

- Following the storage instructions on food packaging and monitoring use-by dates.

If manufacturers cook food and then chill it down, it should be chilled as quickly as possible to prevent bacterial growth. Most manufacturers will have specialised equipment, such as blast chillers. Smaller manufacturers may use other methods, but it is important to include them in HACCP systems.

Personal hygiene in manufacturing

Personal hygiene is vital when working with food. It includes many different aspects of the body, clothing and habits, such as handwashing, protective clothing, hair, jewellery, smoking, illnesses etc. If staff do not follow good personal hygiene practices, they can contaminate food with hazards through direct contact and cross-contamination.

Manufacturers should instruct and train their staff on the expected standards of personal hygiene when working with food.

It can include (this list is not exhaustive):

- Keeping hair, body and hands clean.

- Washing hands regularly and thoroughly, e.g. after visiting the toilet, after handling raw meat and before handling ready-to-eat/cooked food. There should be handwash basins (with hot and cold water and soap) sited within a reasonable distance of food preparation and processing areas.

- Tying hair back and covering it with a hairnet and/or hat.

- Short fingernails, no false fingernails and no nail varnish.

- No jewellery or watches, except a plain wedding band.

- No strong perfumes or other toiletries, which could taint food.

- Wearing clean clothes and suitable protective clothing, such as hairnets, gloves, overalls and aprons, and changing it regularly. Protective clothing should not be worn outside of food areas.

- No coughing or sneezing over food and preparation and processing areas.

- No smoking, eating or drinking when handling food.

- Discouraging behaviours, e.g. touching the face/hair, spitting, chewing gum and picking teeth/nose.

Under Regulation 852/2004, food handlers must maintain high standards of personal hygiene and cleanliness.

Staff illnesses

If workers are ill, it can compromise food safety. Food manufacturers have a legal responsibility to ensure that staff do not handle food if they have an infection. It also applies if they show any symptoms of food poisoning, e.g. vomiting and diarrhoea, and have any infected wounds, skin infections or sores. Any cuts and sores should be covered with brightly coloured waterproof plasters or dressings, even if they are not infected.

Food manufacturers should have reporting procedures for when food handlers have gastrointestinal symptoms, Hepatitis A, and wounds, sores and skin conditions. If a worker has diarrhoea or vomiting, they should report it to their manager/supervisor immediately. If they are at home, they should stay there or go home straight away if they are at work. They must not return to work until 48 hours after their symptoms have stopped.

Food allergens in manufacturing

Legally, manufacturers must inform customers in writing if any of the 14 allergens are in the ingredients of the food/drink they manufacture, supply and sell. It will apply to pre-packed, pre-packed for direct sale (PPDS) and non-pre-packed (loose) food.

Pre-packed

These are foods that are already in packaging before being sold. They are in packaging that has to be opened to be altered and are ready for sale. Most manufacturers will produce food that is pre-packed and will be required to comply with allergen labelling requirements.

There must be an ingredients list on all pre-packed food, with all of the allergens emphasised, e.g. in bold or underlined.

Pre-packed for direct sale (PPDS)

PPDS foods are prepared and packed on the same premises where sold and before they are ordered or selected by customers. This will apply if manufacturers make food on-site and put it in packaging ready for sale, e.g. if they have a staff canteen.

The regulations have recently changed regarding PPDS food. Natasha’s Law came into force on 1st October 2021. Businesses must now label PPDS foods with a full ingredients list, with all of the allergens emphasised, on the packaging.

The Food Standards Agency (FSA) has further information on the allergen labelling changes for PPDS foods.

Non-pre-packed (loose)

Non-pre-packed foods will include unpackaged foods served to customers, e.g. cooked food, hot drinks made to order and any loose unpackaged foods selected from displays. This may apply to manufacturers that have staff canteens.

Food operators must provide allergen information for all loose foods containing any of the 14 allergens. They can do this by adding complete allergen information to menus or putting it on a chalkboard. They can also provide written information packs or a notice informing consumers on how to obtain allergen information.

Precautions

Food manufacturers must ensure that food allergens are managed and controlled effectively in their facilities to prevent cross-contact, which can be achieved by:

- Using reputable suppliers that have gone through an approval process.

- Following good manufacturing practices.

- Including allergenic hazards in HACCP systems and putting controls in place.

- Providing allergen training for staff.

- Looking for hidden allergenic ingredients, e.g. Worcestershire sauce contains anchovies (fish).

- Storing, preparing and processing allergen-containing products separately from non-allergen products, e.g. having separate areas, production lines, equipment, materials and staff.

- Cleaning and disinfecting surfaces, lines and equipment thoroughly where separation is not possible. It is advisable to test for allergens within the facility.

- Carefully checking raw material and ingredients labels for allergens.

- Labelling any ingredient containers clearly with the allergens they contain.

- Labelling allergen-free foods and keeping them separate during transport.

- Recording allergen information accurately, including product specification sheets, ingredients labels and recipes of the dishes.

Unlike bacteria, allergens are not affected by cooking. Manufacturers will also need to consider various dietary requirements and food intolerances. Avoid cross-contact as much as possible when preparing and handling food.

Safely storing food in manufacturing

What food manufacturers store will depend on what they manufacture. They may keep a variety of foods on the premises, such as:

- Ambient, e.g. pasta, rice, sauces, herbs, spices, oils, jams, bread, tinned foods and some vegetables.

- Chilled, e.g. refrigerated foods, such as meat, poultry, fish, seafood, salads, chilled sauces, liquid egg, dairy products (cheese, milk and cream) and ready meals.

- Frozen, e.g. foods kept in freezers such as ice, fish, seafood, meat, poultry and vegetables.

Store foods correctly to prevent contamination from food hazards. Here are some top tips:

- Check all food deliveries before putting them into storage and reject anything that could compromise food safety and quality.

- Keep dry goods in sealed, labelled containers and ensure the storage area is dry and cool.

- Keep storage areas clean and tidy.

- Do not store any food, equipment or utensils on the ground.

- Have an effective stock rotation system, e.g. First In First Out (FIFO).

- Regularly check the temperatures of refrigerators and freezers.

- Always follow the storage instructions on the packaging.

- Where possible, store raw and ready-to-eat foods separately. If it is not possible, keep higher risk foods, e.g. raw meat and poultry, below ready-to-eat and cooked foods.

- Store allergen-containing foods away from allergen-free foods.

- Store chemicals and cleaning equipment away from food storage areas.

- Keep an eye on use-by dates and best before dates, and dispose of any food that has expired. Using food beyond its use-by date is unlawful.

- Label any non-pre-packed foods with the name and any allergens.

- Label any chilled and frozen food with dates put into storage.

Hot holding

Hot holding food provides a perfect opportunity for harmful bacteria to grow if it is not at the correct temperature. Manufacturers may hot hold food as part of their processes or when providing for staff in canteens.

When hot holding food, it must be at a temperature of 63°C or above. Food can be kept below this temperature for up to two hours.

However, if not used after this time, it should be:

- Reheated until it is steaming hot and put back into hot holding (only reheat once).

- Cooled as quickly as possible to a temperature of 8°C or below.

- Disposed of if it has been out for more than two hours.

It is always best to throw out any leftovers to minimise the risk of food poisoning.

Chilled display

Some manufacturers may display chilled food for sale, e.g. in canteens. Before putting any food into chilled units, they must be at the correct temperature before use, i.e. set at 5°C or below. The temperature should be checked at least once a day (using a clean probe between chilled food packs). Display all chilled food for the shortest possible time.

Chilled and frozen food must be transported to customers in temperature-controlled vehicles that record temperatures. Manufacturers must only use approved transport companies for transporting food.

If holding cold foods, e.g. in canteens, they should be kept below 8°C, but ideally between 0-5°C. Chilled food can be held above 8°C for up to four hours, but only once. After this time, the food should be disposed of properly.

Safely serving food in manufacturing

Food contamination can also occur during food preparation and service. This will apply where food manufacturers have canteens or restaurants where staff and visitors can purchase food.

All serving areas and equipment should be kept in good repair and clean. All staff handling and serving food must maintain a high standard of personal hygiene at all times.

When serving food:

- Take extra care when handling and serving ready-to-eat foods, as bacteria and allergens will not be killed by cooking or reheating.

- Provide and use utensils to serve wherever possible to avoid direct touching of food.

- Use gloves when serving and change them regularly.

- Follow hot holding guidance where food has to be kept hot before serving, and the same for chilled.

- Always follow the 4Cs.

Waste management in manufacturing

The type of waste a manufacturer will produce will depend on the product it manufactures, but it is likely to be mostly food, packaging and water waste. If waste management is inadequate, it can encourage pests and may even result in infestations, especially when food starts to deteriorate and becomes odorous. It can also increase the risk of food becoming contaminated with harmful pathogens.

All manufacturers must have appropriate provisions for the segregation, storage and removal of waste, for example:

- Having more efficient processes to reduce the amount of waste produced and rework/recycle were possible. This will also save the business money.

- Having an approved and licensed waste carrier to remove waste.

- Not allowing waste to accumulate by removing it regularly from food preparation and processing areas.

- Having appropriate bins inside and outside the premises, e.g.:

– Sufficient in number.

– Different types of bins for different wastes.

– Bins with foot pedals, so no hand touching.

– Bins with tight-fitting lids to prevent pests.

– Appropriate labelling on bins to ensure staff dispose of waste correctly. - Cleaning and disinfecting bins regularly.

- Lining bins with appropriate liners.

- Regularly emptying bins inside and outside.

- Ensuring bins are placed and kept in areas designated for waste disposal.

- Keeping outside bins locked when not in use.

Some foods, such as raw meat and eggs and untreated milk, require specialist disposal and must not be disposed of in general waste.

Pest control in manufacturing

A pest is any insect or animal which can contaminate food with harmful pathogens and become an infestation if uncontrolled. They can also introduce physical hazards, e.g. contaminating food with droppings, feathers, fur or the pest itself.

Pests in food businesses are relatively common, and EHOs close down food businesses due to pest infestations more than any other problem.

Many different types of pests can contaminate food. The ones that may be in and around food manufacturing may include:

- Rodents – Mice and rats.

- Insects – Flies, ants and cockroaches.

- Stored product insects – Beetles, particularly weevils, can be found in flours, grains and cereals.

- Birds – Pigeons.

Some examples of pest prevention and control methods include:

- Checking the premises regularly and trying to spot gaps or holes that could allow pests into buildings.

- Training staff to spot the signs of pests and how to report.

- Ensuring that external areas around the premises are kept clear of vegetation and anything that could encourage or harbour pests.

- Looking for evidence of pests or pest damage when checking deliveries, e.g. insects or gnawed packaging. Do not accept deliveries if there are any signs.

- Keeping the premises clean and tidy, especially where food is stored, prepared and processed.

- Removing internal and external waste regularly.

- Using fly screens on any open windows and other pest control methods.

- Not having open bins and keeping lids closed when not in use.

- Storing food correctly, e.g. not on the floor, and keeping it covered or well-sealed.

- Having an approved contractor to manage and monitor pest control within and around the premises and contacting them if there are any signs of an infestation.

- Taking extreme care to ensure any pest control chemicals used do not contaminate food.

- Disposing of any food touched by pests.

The Food Standards Agency (FSA) has a web tool called MyHACCP, which can help small manufacturers develop their food safety management and HACCP systems. Using this system can help businesses comply with food safety and hygiene legislation. There are also standards, such as BRCGS Standard for Food Safety, SALSA or ISO 22000, that food manufacturers can use to show their commitment to food safety.

We also offer various food hygiene and HACCP courses, which can help manufacturers understand their legal obligations and succeed in EHO inspections.